In an era where electronic systems operate in increasingly crowded electromagnetic environments, electromagnetic shielding (EM shielding) has become indispensable for ensuring signal integrity, data security, and equipment longevity. From military communication arrays to medical imaging devices, industries rely on specialized materials and engineering to block unwanted interference. Dingmetal, a leader in precision metal fabrication, has emerged as a trusted partner by developing advanced EM shielding solutions that balance performance, durability, and compliance with global standards.

Material Science for Optimal Attenuation

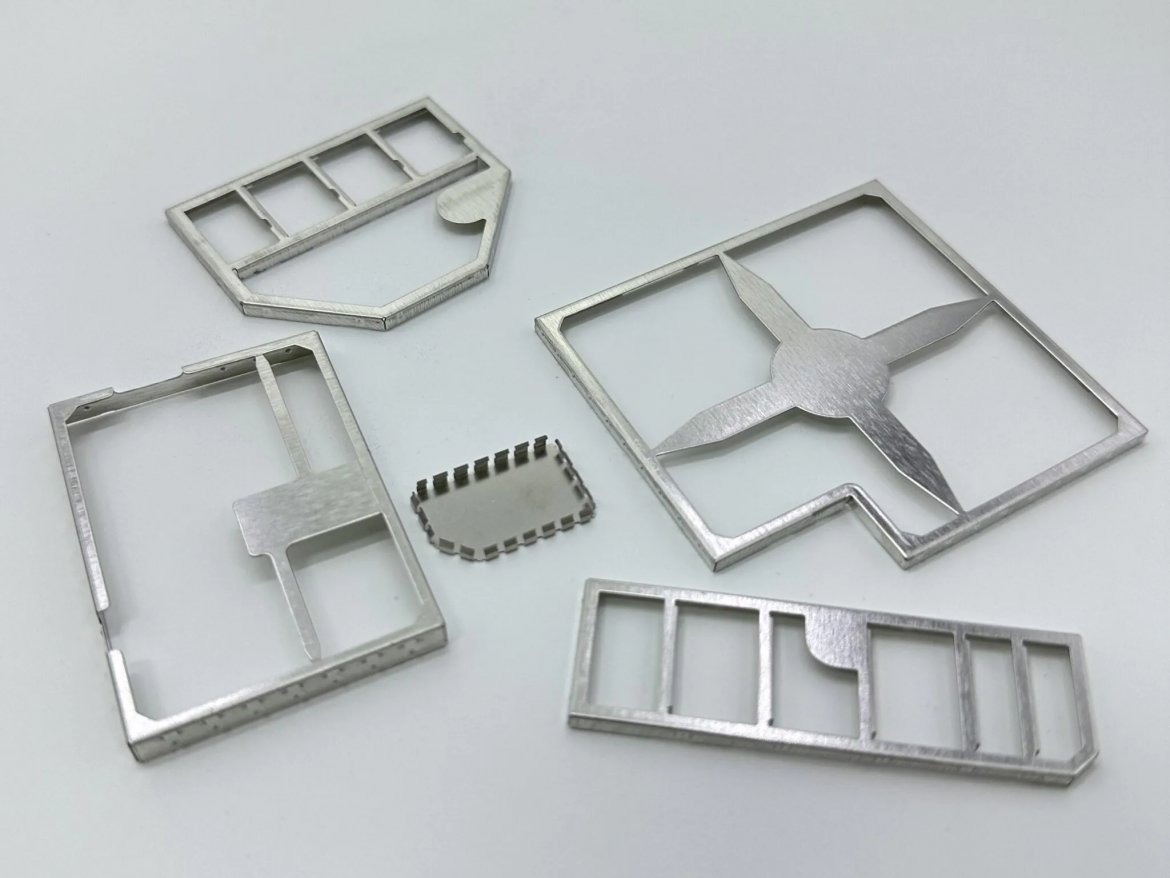

Dingmetal’s EM shielding products leverage materials engineered to absorb or reflect electromagnetic waves across frequency ranges from 10 kHz to 40 GHz. For high-frequency applications like 5G infrastructure, the company uses copper-nickel alloys with controlled conductivity and magnetic permeability, achieving shielding effectiveness (SE) exceeding 80 dB. In medical environments, where MRI compatibility is critical, Dingmetal fabricates enclosures from non-ferrous aluminum alloys with anodized finishes, preventing magnetic distortion while maintaining SE values above 60 dB. A recent project for a satellite manufacturer involved designing a lightweight titanium shield with laser-welded seams, reducing electromagnetic leakage in space-grade conditions.

Enabling Technological Resilience Through Expertise

As electronic systems grow more sophisticated, the demand for tailored EM shielding solutions will only intensify. Dingmetal’s ability to combine material innovation, custom engineering, and compliance expertise positions it as a critical enabler for industries seeking to protect their investments from electromagnetic threats. By transforming shielding challenges into collaborative design opportunities, Dingmetal ensures that clients’ technologies remain reliable, secure, and future-ready in an interconnected world.