The simple answer to whether chickens require light for increased egg laying is an emphatic yes. However, for commercial operations, it is crucial to understand that it is not merely the presence of light, but the precise duration, intensity, and spectrum that dictates production success. Light acts as the primary non-nutritional trigger for the hen’s reproductive cycle, making the lighting system an invaluable tool for maximizing output and maintaining the longevity of the flock’s peak performance.

The practice of using egg laying lights for chickens moves from a rudimentary task in a backyard setting to a highly controlled science in a professional environment, relying on specialized LED systems engineered for photostimulation. Experts like szAMB develop these systems to precisely manipulate the hen’s endocrine system, ensuring predictable and profitable results.

Photoperiod: The Biological Switch for Egg Laying

The biological requirement for increased egg laying centers on the hen’s perception of day length, or photoperiod. Light duration controls the release of key hormones from the brain.

The Mechanism of Photostimulation

When a hen perceives an increase in the number of hours of daylight, specialized photoreceptors located deep within the brain—specifically the hypothalamus—trigger the release of gonadotropin-releasing hormone (GnRH). This hormonal cascade is the direct signal to the ovaries to mature follicles and begin the ovulatory cycle.

For commercial chicken coop lighting for egg production, this understanding dictates two rules:

1. The Trigger: To initiate laying, the photoperiod must be suddenly and permanently increased (e.g., from 10 hours of light to 14 hours) when the pullets reach target maturity (typically 18–20 weeks).

2. The Maintenance: Once the light program is increased, it must never be decreased during the hen’s laying life. Any reduction in photoperiod will signal the reproductive system to shut down, leading to an immediate and irreversible drop in egg production.

A consistent light duration of 14 to 16 hours per day is maintained through the peak production cycle to sustain the hormonal flow required for daily egg output.

Spectrum: Why Egg Laying Lights for Chickens Must Be Red-Enhanced

While the duration of light is the trigger, the color or spectrum is the fuel that sustains the hormonal machinery. Unlike human vision, the hen’s photoperiodic system is most sensitive to the longer wavelengths of the light spectrum—the red and orange light.

The Importance of Long Wavelengths

Red light (around 625 nanometers) is critical because it penetrates the hen’s skull and feathers most effectively, ensuring maximum stimulation of those deep brain photoreceptors. Standard white light, especially cool white or blue-enhanced light, is less effective at this biological penetration.

Professional led lights for laying hens are therefore designed to provide a warm color temperature (around 2700K–3000K) or utilize dedicated red LEDs. This spectral tuning ensures:

1. Increased GnRH: Direct stimulation of reproductive hormones, which increases the total number of eggs laid per hen and can prolong the peak production period.

2. Reduced Stress: The warm, reddish light is also generally calming, contributing to reduced aggressive behaviors like feather pecking, a critical welfare concern in high-density layer houses.

This focus on spectral output is a key differentiator between generic chicken coop lighting for egg production and engineered solutions designed for commercial ROI.

Technical Demands for Professional Layer House Lighting

The success of a professional layer operation hinges on the reliability and precision of the lighting system. Generic hardware store fixtures cannot survive, much less provide the precise biological inputs required by the demanding environment of a commercial layer house.

Durability and Control: The szAMB Standard

High-quality egg laying lights for chickens must possess features engineered for the challenges of layer houses, which include high humidity, airborne dust, and corrosive ammonia from manure:

1. IP67 or Higher Rating: Essential to withstand high-pressure, high-temperature washdowns without internal component failure.

2. Ammonia & Acid Resistance: Fixtures must be constructed from corrosion-proof materials to ensure the lighting investment lasts its full intended lifespan.

3. Flicker-Free Dimming: The light must be smoothly dimmable from 0% to 100% without any flicker detectable by the hen. This allows for the necessary gradual “sunrise” and “sunset” light transitions required for welfare and stress management.

The Benefit of DC48V Systems

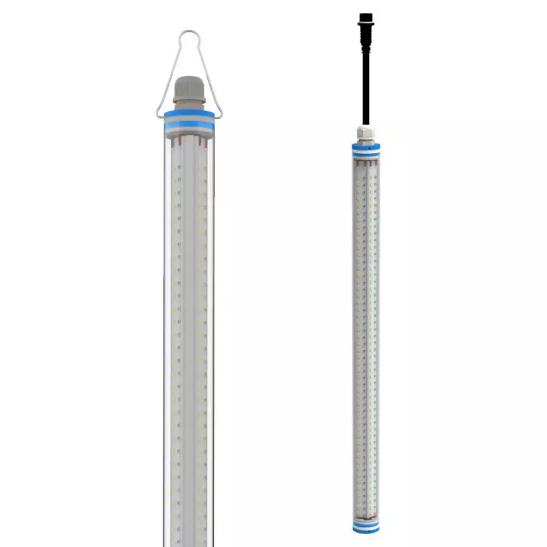

Products in the szAMB layer category (such as the DC48V T5 and T6 tubes) often utilize low-voltage DC48V technology. This is advantageous in large, sprawling facilities, particularly those with metal cages, as it:

1. Enhances Safety: Significantly reduces electrical shock hazards in damp, conductive environments.

2. Improves Uniformity: Allows for longer, synchronized runs without the voltage drop issues that cause uneven brightness across a long barn, ensuring every hen receives the correct photostimulation.

szAMB Layer Solutions: Engineered for Peak Production

The szAMB Layer & Breeder Poultry lighting category provides the technical foundation for a globally competitive egg operation. Products like the DC48V T5, T6, and T12 LED tubes are all built to maximize the layer’s natural capacity:

1. Customized Spectrum: All layer-focused szAMB fixtures are tuned to deliver the warm, red-enhanced light crucial for hormonal stimulation, ensuring the layer house environment actively supports high egg output.

2. Extreme Longevity and ROI: With lifespans often exceeding 80,000 hours and backed by a professional warranty, these led lights for laying hens minimize maintenance downtime and maximize the long-term return on investment.

3. Seamless Integration: Designed to work perfectly with szAMB’s Master & Slave control dimming systems, they guarantee the precision control required for managing the exact light programs (photoperiod and ramp-up/ramp-down) necessary throughout the hen’s life.

In conclusion, chickens absolutely require the correct light for increased egg laying. However, simply hanging a basic bulb is not enough. The future of production requires a scientifically designed photostimulation program executed by highly durable, spectrally tuned, and precisely controlled szAMB lighting systems, transforming a basic necessity into a powerful tool for maximizing profitability and animal welfare.