Achieving the ideal thermal conductivity in the production of electric car batteries is crucial for both performance and safety. LEAD, a leader among smart manufacturing companies, specializes in solutions that ensure high efficiency in adhesive applications. With a glue utilization rate exceeding 95% and uniform adhesive thickness, LEAD’s technology is setting new standards.

Superior Adhesive Utilization for Enhanced Performance

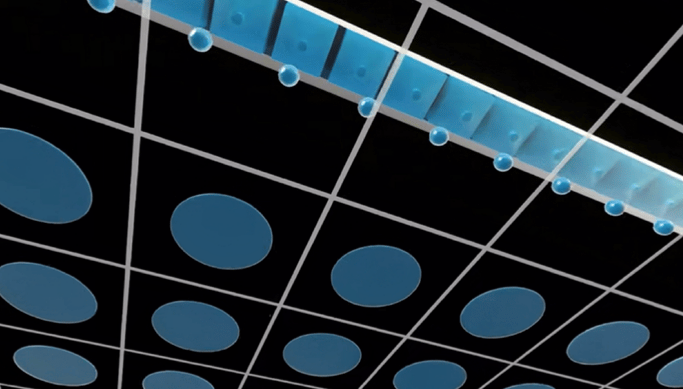

LEAD’s innovative adhesive application minimizes waste while maximizing the effectiveness of thermal management materials. This efficiency is essential for maintaining battery performance and longevity, ensuring safe operation under various conditions.

Consistent Adhesive Thickness for Optimal Thermal Management

Another significant advantage of LEAD’s technology is the uniform and consistent adhesive thickness. This feature is vital in electric car battery manufacturing, as it guarantees effective thermal conductivity across all components. By providing a consistent application, LEAD enhances the reliability of thermal management solutions, which is critical for the safety and performance of electric vehicles.

Conclusion

LEAD’s advanced adhesive technologies significantly enhance thermal conductivity in electric car battery manufacturing. By focusing on high glue utilization and consistent adhesive application, LEAD offers solutions that improve efficiency and reliability. As a prominent brand in smart manufacturing, LEAD is committed to driving innovation in battery production, ensuring safety and performance in every electric vehicle.